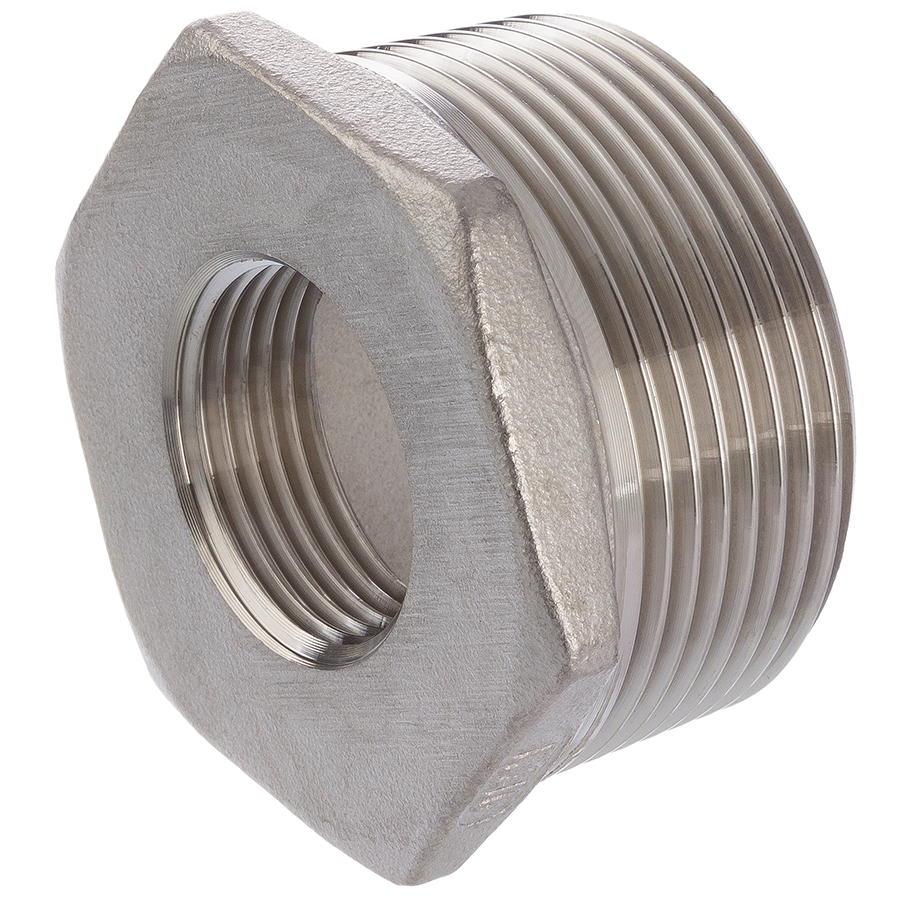

Stainless steel V4A fittings

In our online shop you will find a large assortment of high quality stainless steel threaded fittings made of AISI 316 stainless steel (UNE EN 10213-4 / DIN 1.4408) formerly and in everyday language referred to as A4 stainless steel.

The addition of 2% molybdenum makes AISI 316 stainless steel - stainless steel A4 – therefor more corrosion resistant to salt water and chlorinated water. This is why stainless steel fittings made of A4 stainless steel are very well suited for marine applications, swimming pools and industrial applications. They are suitable for high corrosion resistance.

In our online shop you will find all kinds of stainless steel fittings - from A4 stainless steel sockets and A4 stainless steel T-pieces to A4 stainless steel elbows. A comprehensive range of A4 stainless steel hose nozzlesand special fittings such as A4 stainless steel tank connectors with teflon seal for the highest demands.

Stainless steel threaded fittings made of A4 stainless steel, quality AISI 316

Features of the stainless steel fittings at a glance:

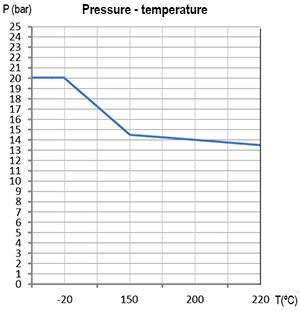

16,5 bar | 100°C

15 bar | 150°C

13,5 bar | 220°C

Basic technical data for our stainless steel fittings:

- Working temperature -20°C to 200°C

- Working pressure PN 20 bar (300 psi)

- Dimensioning according to ISO 4144

- Whitworth thread, CNC machined according to standard ISO 7/1 (DIN 2999 / BS21)

- Manufacturing standard UNE EN 10213-4, tolerance DIN 1.4408

Possible usage for V4A stainless steel fittings

Due to the special properties of the material, these fittings are often used in coastal regions. While a A2 fitting would start to rust due to the high salt content in the air, the A4 stainless steel fitting withstands the coastal weather. Furthermore, their acid resistance makes them suitable for use in the chemical, food, petrochemical and natural gas industries. Also, they can be used in corrosive environments and extreme temperatures, such as used in fluid technology, boilers, condensers, heat exchangers and reactors.

Stainless steel AISI 316 (material 1.4401)

Stainless steel AISI 316 also known as material 1.4401(X5CrNiMo17-12-2, contains an addition of molybdenum, which improves the resistance to corrosion. According to DVGW worksheet W541 (basis for the requirement of stainless steel pipes for domestic drinking water installation), the steel material 1.4401 is most commonly used for drinking water installations.

Stainless steel fittings made of AISI 316 stainless steel are listed in the *UBA list for drinking water-compatible materials in the drinking water installation and can accordingly be used for drinking water supply.

What is A4 stainless steel?

Stainless steel according to EN 10020) is a name for alloyed or unalloyed steels with a special degree of purity. Consequently, this refers to steels whose sulfur and phosphorus content (so-called iron companions) does not exceed the value of 0.025%.

The alloy 316 is a standard grade steel with molybdenum. The molybdenum not only gives the alloy a better corrosion resistance than A2 stainless steel, but also a higher resistance to pitting and crevice corrosion in media containing chloride. The austenitic structure imparts a high degree of toughness to this alloy, even at cryogenic temperatures, high creep strength, creep rupture strength and tensile strength at elevated temperatures. The alloy is also known as A4 stainless steel.

The thread

All threads are by default specified in inches. For better illustration the approximate dimension is also stored in mm. Please also note our information sheet downloads as .pdf "the cross piece with customs, or why 1" is not 25.4mm"

The internal thread (designation "Rp") is parrallel / cylindrical and the external thread (designation "R") is conical. The nuts of screwed connections are parallel threads (ISO 228-1).

Metal threaded joints can be sealed with Teflon tape, Teflon thread, but also in contrast to plastic fittings with hemp or similar, for instance foam sealing material.

Assortment of products

For the connection of pipes we carry a different veriety of stainless steel fittings: from pure internal threads (IG)to combinations of female and male threads, up to male threads (AG). In addition, our product range covers a wide variety of connection options. For pipes that run the shape of an elbow, our stainless steel A4 elbow 45 ° or A4 elbow 90 ° would be ideal. Also versions as A4 cross-pieces or A4 Y-pieces are available in our online shop. In addition, you will find tube and double nipple V4A , A4 stainless steel hose nozzles or reducers, such the reducer sleeve A4 , to connect pipes of unequal nominal sizes.

A big advantage of threaded fittings is their flexibility. Unlike press fittings or welding fittings, threaded connections can always be loosened.

Discover now our valves made of A4 stainless steel or our A4 stainless steel press fittings .