Description

Hose Coupling Lever Arm Coupling System Kamlock Stainless Steel V4A Type C Female Part with Hose Tail

The Kamlock couplings originated in the USA and are certainly one of the most widely used coupling types worldwide. The foundation was the standard of the American military.

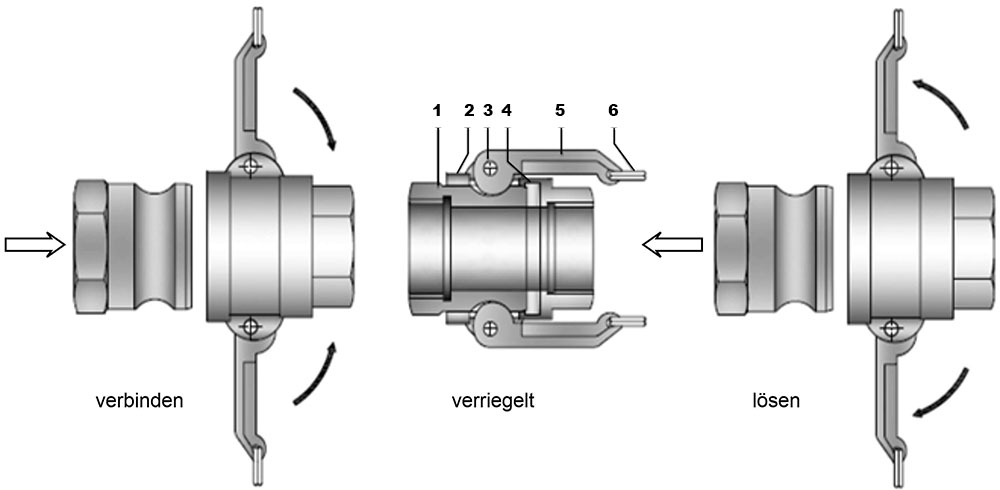

The Kamlock hose coupling quick coupling program is distinguished by its simple locking system. A family that logically consists of male and female parts, complementing each other, making it universally usable in agriculture, industry, and private households for appealing installations.

Choosing the right components is manageable without extensive technical knowledge, as "male" and "female" parts only need to have identical dimensions (dimension "B") – in our offerings, the B dimension must always be identical. Connections with internal or external threads feature the European BSP pipe thread G and are compatible with all fittings with this inch thread (BSP G).

Type C coupling is compatible with Type E, A, and F plugs as well as with end cap Type DP.

- Plug (Male Part) Stainless Steel V4A 1.4408

- Coupling (Female Part) Stainless Steel V4A 1.4408

- Pin Galvanized Steel

- Flat Gasket NBR

- Lever V2A Stainless Steel

- Ring Anodized Steel

Stainless Steel (according to EN 10020) is a designation for alloyed or unalloyed steels with a special degree of purity. Steels whose sulfur and phosphorus content (called iron companions) does not exceed 0.025%.

The 316 alloy is a standard steel type with molybdenum. Molybdenum gives the 316 alloy better corrosion resistance than 304, especially higher resistance to pitting and crevice corrosion in chloride-containing media. The austenitic structure gives this alloy a high degree of toughness, even at cryogenic temperatures, high creep strength, time-dependent strength, and tensile strength at elevated temperatures. This alloy is commonly known as V4A Stainless Steel.

Stainless Steel AISI 316 | Material 1.4401 (X5CrNiMo17-12-2) (V4A) Application: According to the DVGW guideline W541 (basis for the requirements for pipes made of stainless steels for drinking water installation), the steel material 1.4401 is most commonly used.

Used in various applications in the chemical, petrochemical, and natural gas industries, food industry, corrosive environments, and extreme temperatures... Fluid technology, boilers, condensers, heat exchangers, reactors...

Verantwortliche Person für die EU

In der EU ansässiger Wirtschaftsbeteiligter, der sicherstellt, dass das Produkt den erforderlichen Vorschriften entspricht:

HT CONNECT GmbH & Co. KG

Norisstraße 4

91257 Pegnitz

Kontakt:

E-Mail: info@ht-connect.de

Media

There are currently no media files available.