Description

Outlet Tap Stainless Steel Faucet, Quality AISI 316, V4A

Not an off-the-shelf tap - the stainless steel faucet from  . Connection sizes tailored to our needs!

. Connection sizes tailored to our needs!

Note: Slim, ergonomic design with practical threaded connections - G1 = BSP G thread - hose nozzle connection with standardized BSP G thread, also suitable for connecting threaded fittings.

Connection:

Male thread x Male thread (plus screwable hose nozzle)

Thread:

BSP Pipe Thread G DIN 2999 & BS21, ISO 228/1 & ISO 7/1, not self-sealing, sealing with hemp, sealing paste or similar.

Temperature:

-20°C to 80°C (EPDM seal for screwable hose nozzle)

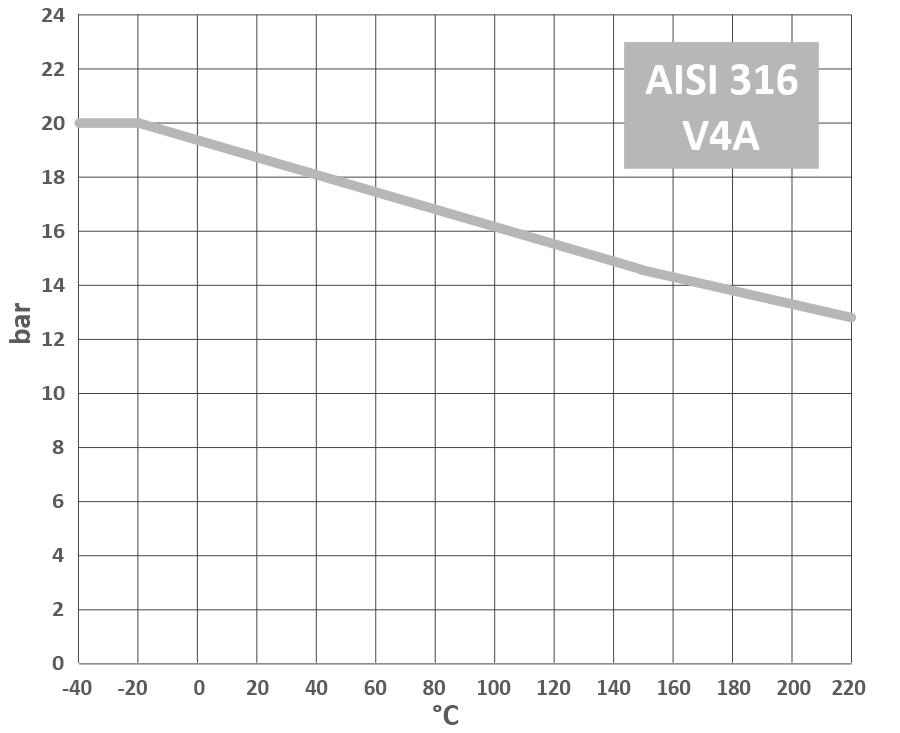

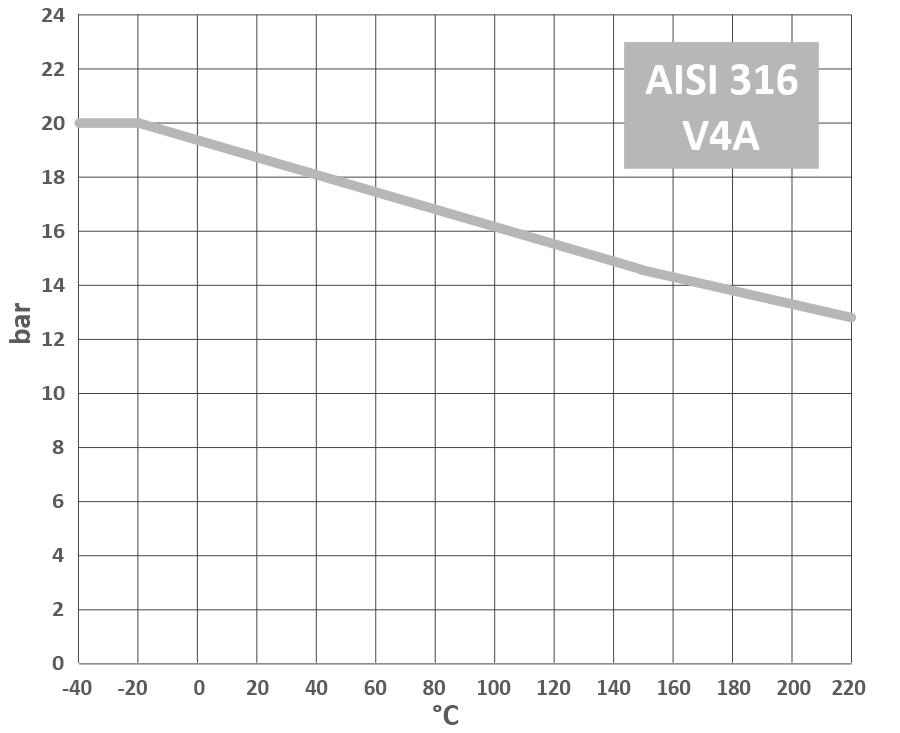

Working pressure (PN):

20 bar

Material:

Stainless Steel AISI 316 V4A (UNE EN 10213-4 / DIN 1.4408)

Special feature:

Lever lock safety

DIN:

Dimensions according to ISO 4144, connection thread according to ISO 7/1 (DIN 2999 / BS 21)

Color:

Gray stainless steel

Key Data

- Operating temperature -20°C to 200°C

- Working pressure PN 20 bar (300 psi)

- Dimensions according to ISO 4144

- Whitworth thread, CNC milled according to ISO 7/1 (DIN 2999 / BS21)

- Manufacturing standard UNE EN 10213-4, tolerance DIN 1.4408

Stainless steel (according to EN 10020) is a designation for alloyed or unalloyed steels with a special degree of purity. Steels whose sulfur and phosphorus content (so-called iron companions) does not exceed 0.025%.

The alloy 316 is a standard steel grade with molybdenum. Molybdenum gives alloy 316 better corrosion resistance than 304, particularly higher resistance to pitting and crevice corrosion in chloride-containing media. The austenitic structure gives this alloy a high degree of toughness, even at very low temperatures, high creep resistance, rupture strength and tensile strength at elevated temperatures. The alloy is commonly known as V4A stainless steel.

Stainless steel AISI 316 | Material 1.4401 (X5CrNiMo17-12-2) (V4A) Application: According to DVGW Worksheet W541 (basis for the requirements for pipes made of stainless steels for drinking water domestic installation), the steel grade 1.4401 is the most commonly used.

Usable in a wide variety of applications in the chemical, petrochemical and natural gas industries, food industry, corrosive environments and extreme temperatures ... fluid technology, boilers, condensers, heat exchangers, reactors ...

. Connection sizes tailored to our needs!

. Connection sizes tailored to our needs!

Key Data

- Operating temperature -20°C to 200°C

- Working pressure PN 20 bar (300 psi)

- Dimensions according to ISO 4144

- Whitworth thread, CNC milled according to ISO 7/1 (DIN 2999 / BS21)

- Manufacturing standard UNE EN 10213-4, tolerance DIN 1.4408

Stainless steel (according to EN 10020) is a designation for alloyed or unalloyed steels with a special degree of purity. Steels whose sulfur and phosphorus content (so-called iron companions) does not exceed 0.025%.

The alloy 316 is a standard steel grade with molybdenum. Molybdenum gives alloy 316 better corrosion resistance than 304, particularly higher resistance to pitting and crevice corrosion in chloride-containing media. The austenitic structure gives this alloy a high degree of toughness, even at very low temperatures, high creep resistance, rupture strength and tensile strength at elevated temperatures. The alloy is commonly known as V4A stainless steel.

Stainless steel AISI 316 | Material 1.4401 (X5CrNiMo17-12-2) (V4A) Application: According to DVGW Worksheet W541 (basis for the requirements for pipes made of stainless steels for drinking water domestic installation), the steel grade 1.4401 is the most commonly used.

Usable in a wide variety of applications in the chemical, petrochemical and natural gas industries, food industry, corrosive environments and extreme temperatures ... fluid technology, boilers, condensers, heat exchangers, reactors ...

Verantwortliche Person für die EU

In der EU ansässiger Wirtschaftsbeteiligter, der sicherstellt, dass das Produkt den erforderlichen Vorschriften entspricht:

HT CONNECT GmbH & Co. KG

Norisstraße 4

91257 Pegnitz

Kontakt:

E-Mail: info@ht-connect.de

Media

There are currently no media files available.